2001J Mainline Packers meet the highest standards for testing and sealing joints of mainline sewer pipes with acrylamide, acrylate or urethane gels.

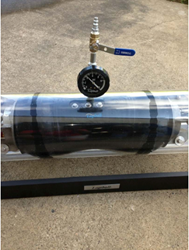

Logiball 2001J Mainline Packers meet the highest standards for testing and sealing joints of mainline sewer pipes with acrylamide, acrylate or urethane gels. A thick, reinforced SBR rubber sleeve is bonded to the stainless-steel core and a layer of softer rubber is applied over the seating portion to provide superior seating against rough surfaces. The smooth outer finish reduces the adherence of the grout on the packer.

Logiball 2001J Mainline Packers come with two grout ports and a third port dedicated for the test medium (air or water).

MAIN FEATURES:

Void Pressure Monitoring Systems: Two different void pressure monitoring systems are available to accurately transmit the void test and grouting pressures to a gauge read by the camera or through a pressure transducer. The conventional localized sensor is recommended for acrylamide and acrylate grouts. The in-wall water chamber sensor is recommended for stickier grouts such as urethane gels and polyurethanes. The 2001J Packer can be ordered with both systems or one of the two as needed by customer.

Dedicated Test Port: By using a dedicated hose from the truck to the packer for the test medium (air/water), “H” blocks are eliminated and the mixing ratio of the two-part grout is kept constant (no flushing of the catalyst when testing).

Features

Three-Function Adjustable Rubber Check-Valve: They provide added safety against syphoning the tanks and unwanted backflow contamination into the hoses, and provide a good mixing of the two-part chemicals through the fan like stream of the opposed and adjacent ports.

The Autotesting Concept: When inflating the 2001J packers, the ends first seal against the pipe wall, while its central portion progressively expands, trapping air and water, and compressing it into the mixing chamber. The pressure in the chamber is transmitted through the improved liquid filled sensor and/or the in-wall water chamber sensor to a gauge or transducer installed on the packer. The operator can tell if a joint is obviously good or not by simply inflating the packer over it. By avoiding time consuming conventional tests, productivity could be increased by as much as 30%.

Logiball 2001J Packers approximate void volumes.

ICGA promotes the proper use of chemical grouting as a safe, economical and effective mean to reduce ground water.